360° Scan Inline Inspection

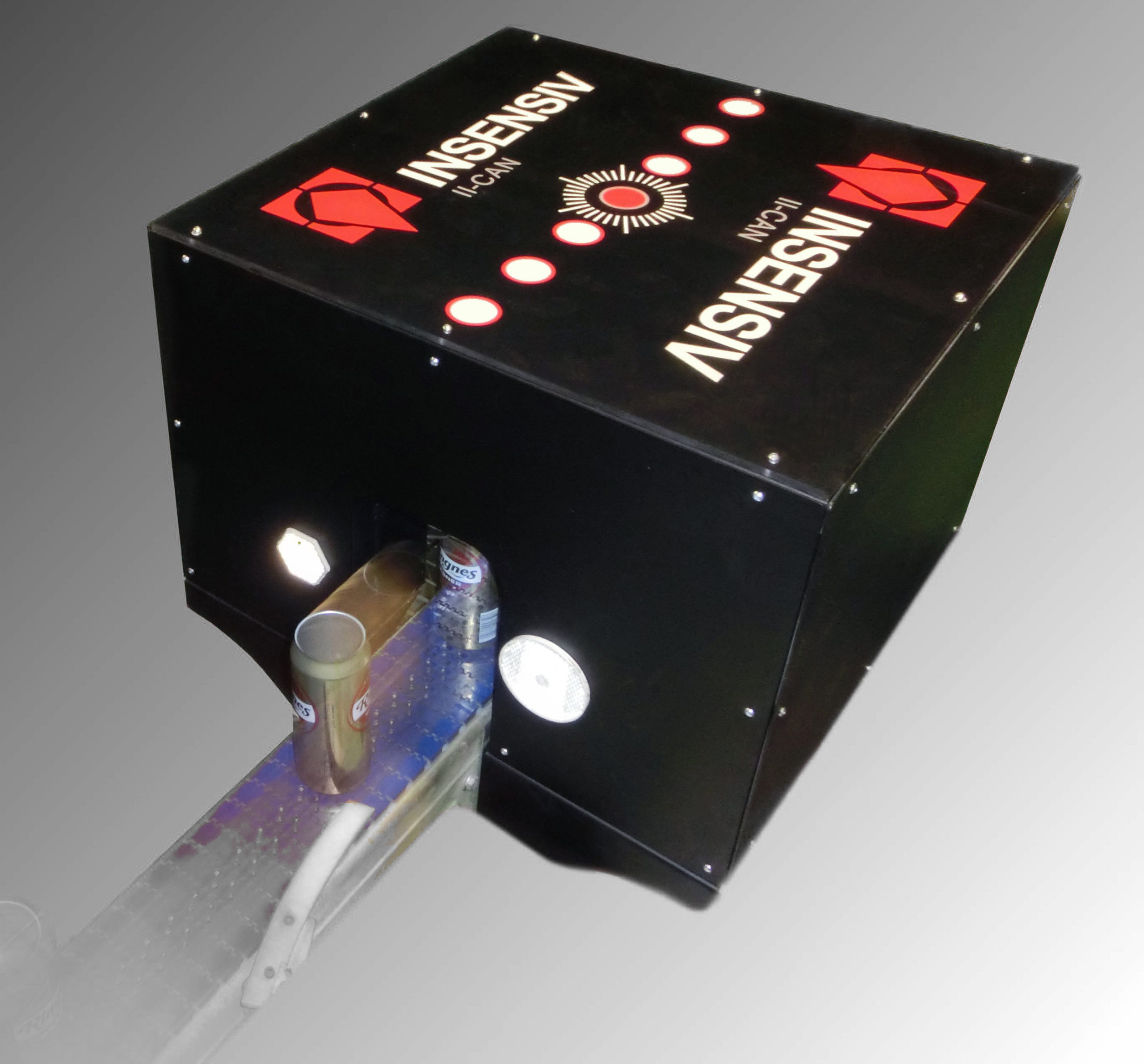

The 360°Scan Inline Inspection System from insensiv offers a solution for your inspection tasks in the packaging sector.

The 360° Inline Inspection System

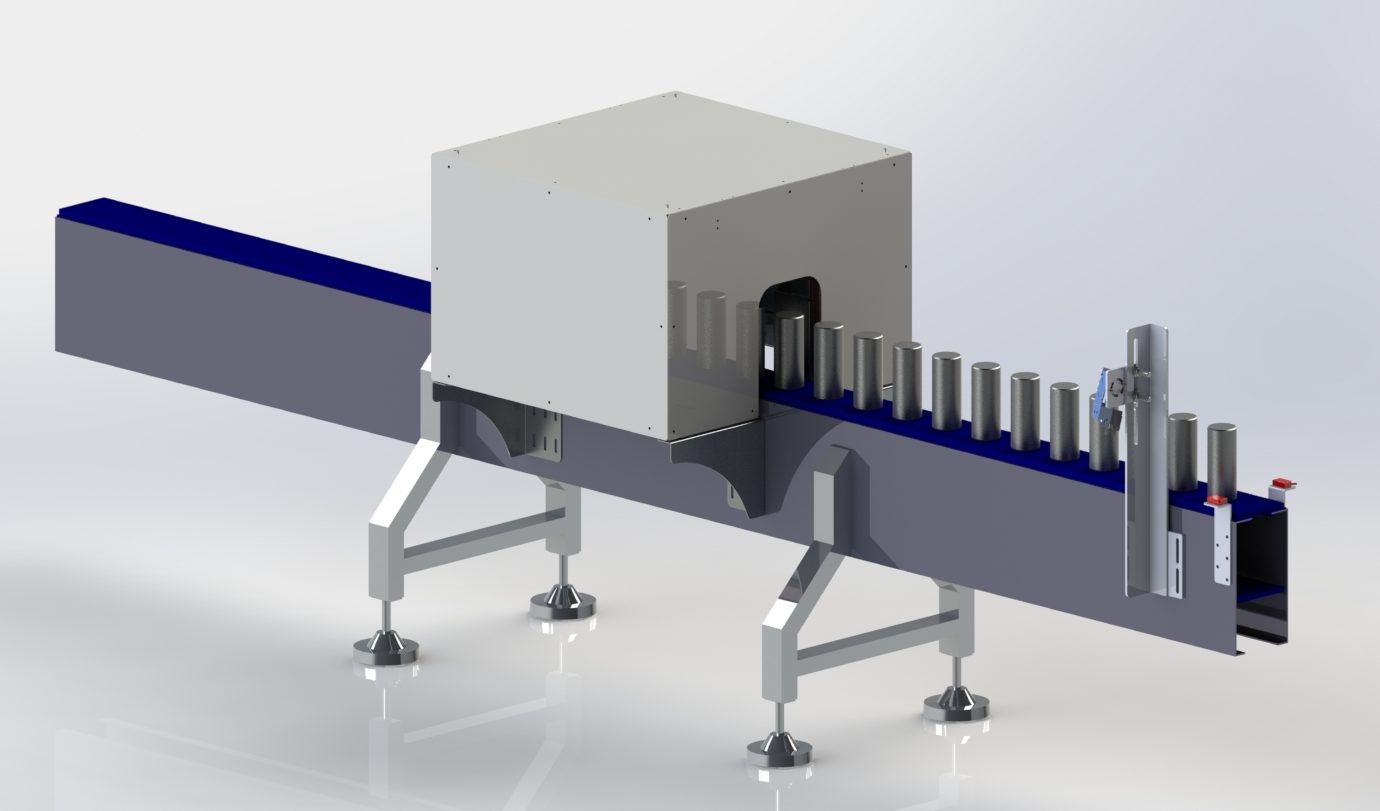

As one of the leading manufacturers of systems for foreign decor detection and decor analysis in the beverage can production and canning segment, we offer you the 360°Scan Inline Inspection System as a solution for inspection tasks in the packaging sector.

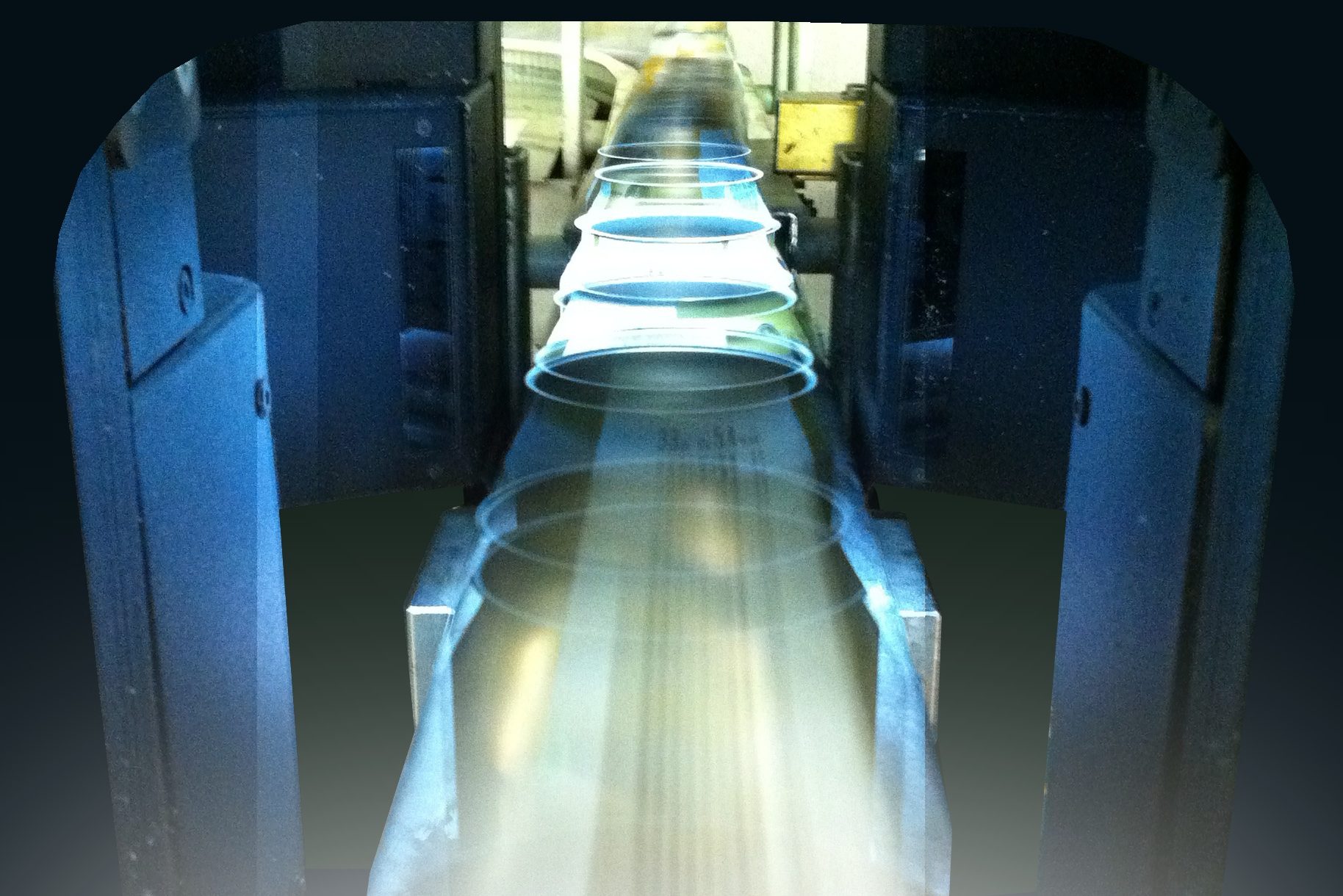

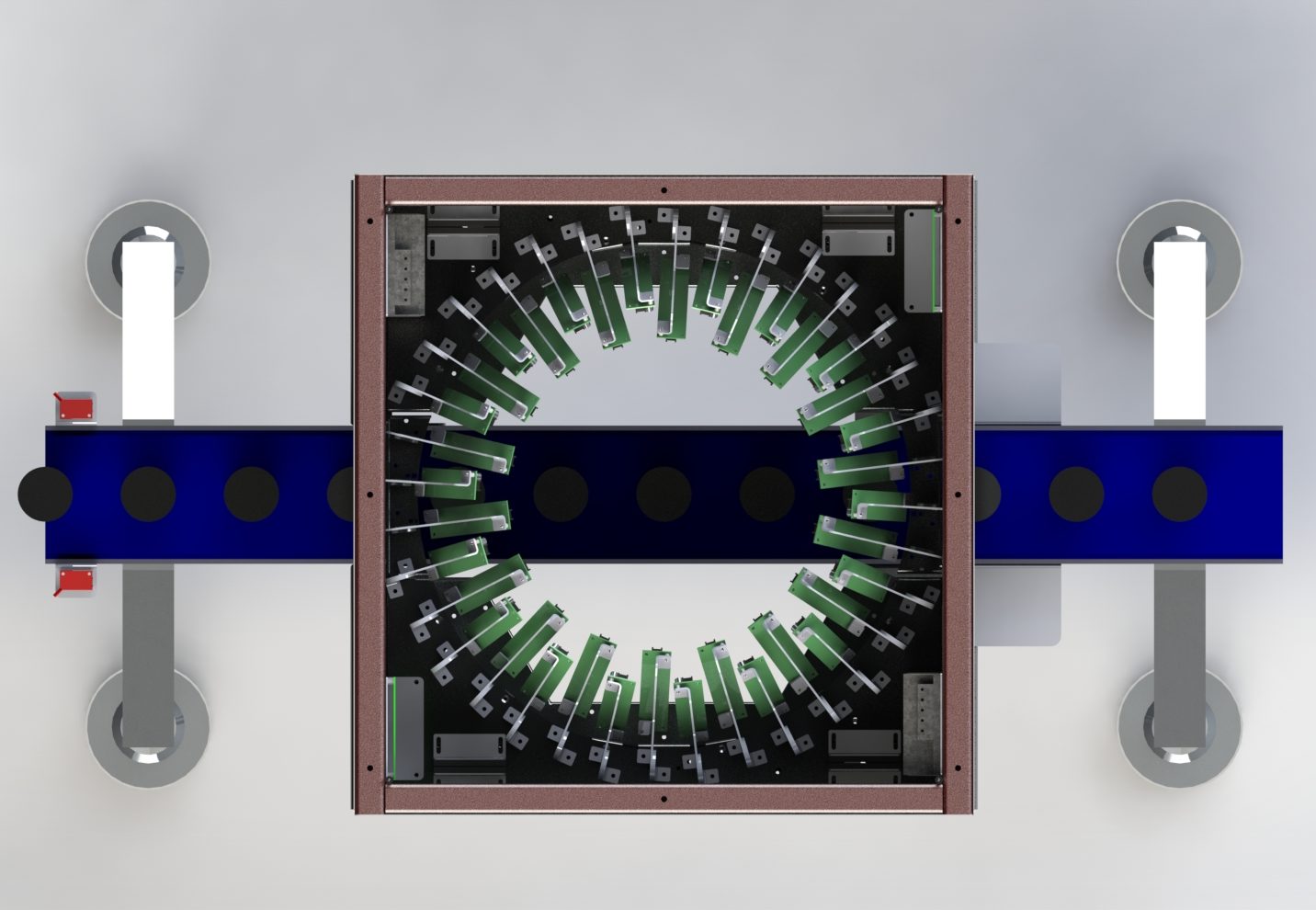

The 360°Scan system works with 6 cameras, which are installed in a 360 degree orientation around the can. A complete surface inspection of each individual can is possible at production speeds of up to 50 cans/s.

The compact design allows an easy integration into your production lines. A wide variety of existing conveyor systems such as horizontal or vertical conveyors are possible

Inspection tasks

Control of the production for faults like:

• foreign cans

• strong fluctuations in the print image

• dents and major scratches

• blank cans

By means of an optionally integrated barcode or OCR module (6 additional cameras) it is also possible to check printed codes. In this way ejection errors can be avoided and the quality of the codes can be checked.

Your advantages at a glance

• High-speed 360° external inspection with up to 50 cans per second

• Optional redundant checking of barcode or OCR

• 100% control of your production and ejection! of defective containers

• Early reaction to manufacturing errors

• Easy integration into existing production lines

• Connection to your internal production control system

• Remote service with short response times

• Minimum cleaning and maintenance effort

• Can be used for a wide range of container types

• Quick “Return on Investment”

Interested?

You need more information about our 360° Scan Inline Inspection System? Download the product flyer or contact us directly. We will be glad to help you.